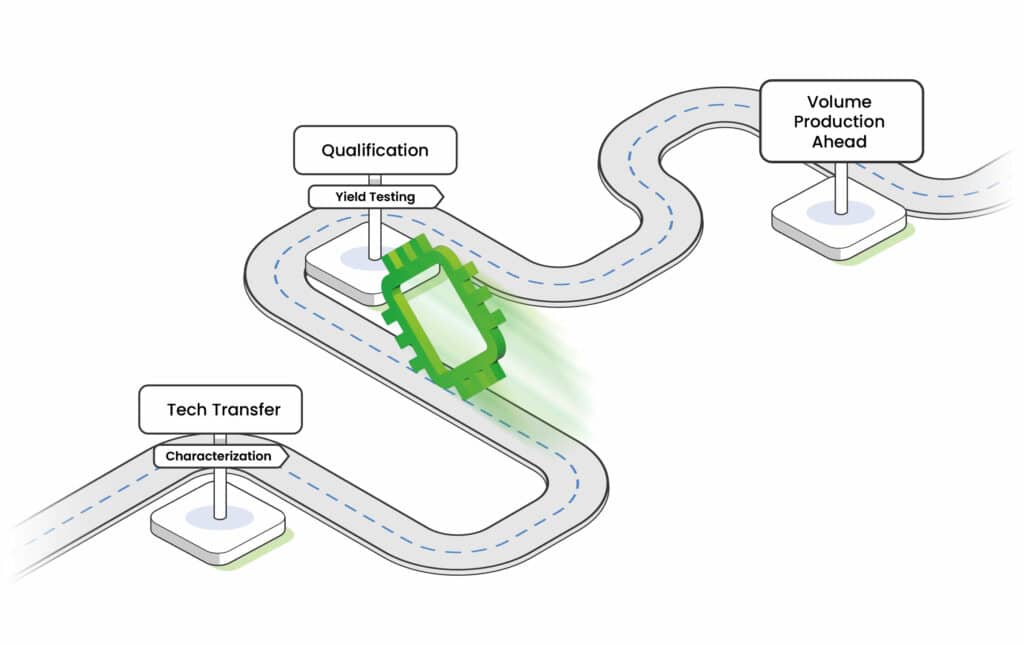

In our last post, we talked about the technology transfer process. This article covers what happens after the technology is transferred to a fab, as Weebit ReRAM continues on the road toward volume production.

The Basics of Qualification

If you’ve perused the Weebit Glossary, you will already know qualification is the process by which a fab ensures a design is ready for mass production, confirming it meets commercial specifications and will continue to do so over the expected lifetime of the product. This includes ensuring that it is stable, operates reliably as designed, and meets yield targets and quality standards.

One of the biggest parts of qualification is failure mode and defect analysis – determining whether any of the many things that could happen to a product during its lifetime will negatively impact it. In simple words – what could go wrong with the product? The first step is figuring out what all those possible things may be, and the next step is putting the product through a rigorous set of tests to determine possible failures.

Whatever the product, testing is focused on how long the expected useful life of that product is. A mobile phone might only need to be tested for three years of use, while a car may need to be tested for 15 years of its expected useful lifetime.

So how do you test a product for all of the stress it might experience over many years? The key lies in amplifying the stress level and applying that stress constantly over a compressed timeframe.

In a 2006 commercial, Ikea explained how in one week they test for three years of expected home use:

Of course, to actually test its products, Ikea uses specially developed machines in sophisticated testing labs, not a nimble, incredibly patient gentleman. But you get the idea.

Accelerated Stress Testing

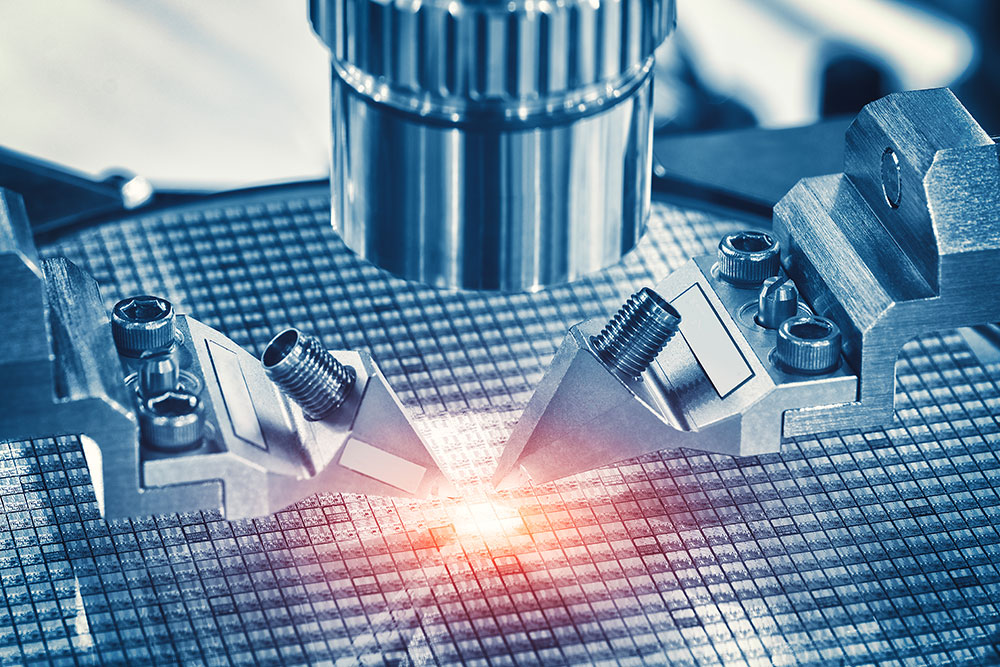

To simulate the effects of environmental factors on a product over its expected lifetime, it’s necessary to devise tests that imitate in an accelerated manner how the product will live its life. Because Non-Volatile Memories (NVMs) have been used in semiconductor products for many years, tests are standardized through industry standards body JEDEC. These tests were developed for flash memories which are the main types of NVMs that have been around in one form or another since 1970.

The most important things we need to test are a memory device’s endurance (the number of Program/Erase cycles it can reliably handle) and its retention (the time period in which data can be reliably stored at a given temperature).

High temperatures can speed up chemical reactions and can negatively impact a product’s lifetime (think spoiled milk). This is true in memories as well, so devices must be tested for endurance and retention under worst-case high temperatures for extended time periods. For example, to ensure a device can maintain data retention for 10 years at 125 degrees Celsius, the equivalent test might subject the device to 200 degrees Celsius constantly for one month.

Devices must also be subjected to thermal shocks, low-temperature programming, and a number of other circumstances. And temperature stress comprises only a fraction of the testing needed for memory device qualification – other factors such as voltage fluctuations, surface mount technology (SMT), and many others, can impact the performance of the device.

Emerging Technology

One of the challenges for ReRAM technology is that it is an emerging technology – and there may be conditions that impact it differently than other NVMs. That said, a lot of the stresses will be the same, so we start with the standard tests that have been developed over the past 50 years. Our team then projects what other possible failure mechanisms might exist and develops specific tests for those. The incredible R&D teams at Weebit and CEA-Leti are experts at this.

In addition to carrying out the required full qualification tests for our ReRAM, we’re also adding in an initial qualification phase. The results of these initial tests will provide customers with the confidence to start designing their products with our ReRAM while we continue with full qualification testing. Once started, initial qualification tests take up to a few months to complete.

After completion of initial qualification, we’ll proceed with full qualification. During this process, Weebit’s embedded ReRAM module will be subjected to more stress at higher temperatures for longer periods of time. This process will include several lots of devices tested consecutively for anywhere between three and six months – accounting for the time it takes for the several lots of wafers to be separately manufactured in the fab.

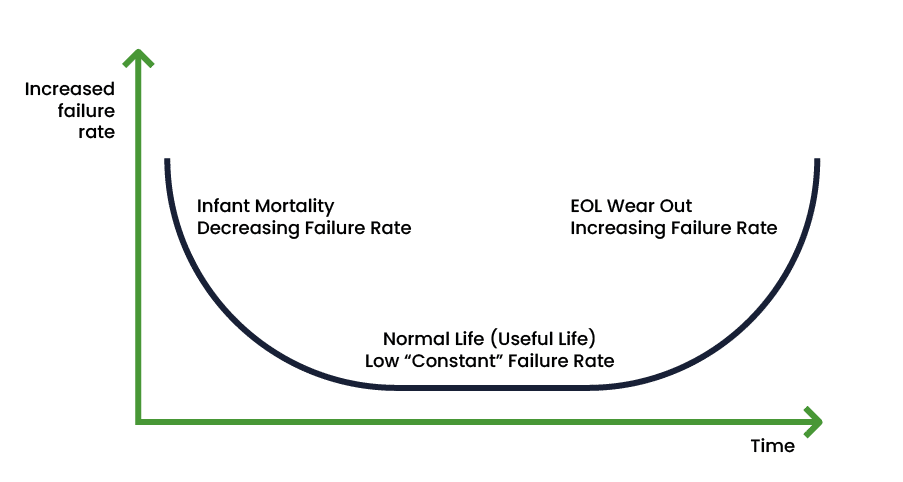

The below industry-standard ‘bathtub curve’ shows how potential failures would normally be expected to occur in a new product. It’s expected that initial defects could cause failures, but those failures will quickly decrease as the product matures. Likewise, toward the end of a product’s life, you’d again expect to see more failures as the product wears out. In the middle of the curve, failures should be quite limited. The initial qualification phase would be expected to identify any early failures and would be a good time for customer designs, while full qualification covers the rest of a product’s expected lifetime.

High Expectations

Qualification is a key part of the semiconductor manufacturing process, and each product must be qualified on every new target process. Right now, Weebit is going through the qualification process of our embedded ReRAM module with Leti, which is expected to wrap up in the second half of the year. In parallel, once the SkyWater silicon is available, we will embark on the qualification of our technology on the SkyWater 130nm process.

While we’re eager to speed through these tests, it’s important to take our time and be rigorous to ensure the final product surpasses quality and performance standards.