Meet the Weebit ReRAM Bitcell

Weebit ReRAM (Resistive Random-Access Memory) addresses the growing need for higher-performance, more reliable, lower-power, and more cost-effective non-volatile memory (NVM) solutions in a broad range of electronic products.

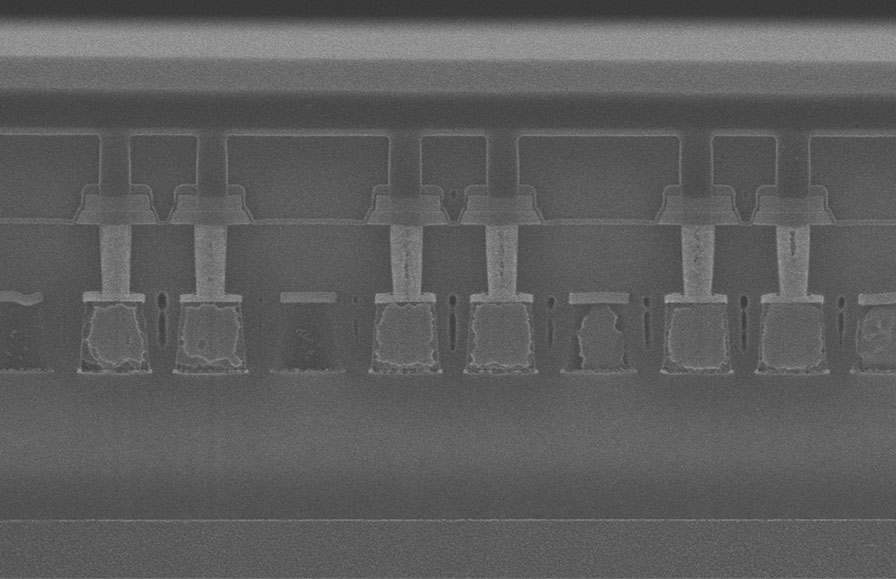

At a basic level, ReRAM (also called RRAM) is a memristor technology. Resistance can be programmed using electric voltage. The Weebit oxide-based ReRAM (OxRAM) cell is comprised of a thin oxide switching layer between two electrodes.

How Weebit ReRAM Works

Immediately after it is manufactured, the memory cell is in a highly resistive state, meaning it will not allow current to flow between electrodes at standard voltage levels. At this point, the metal oxide layer is insulated against electric current. A one-time ‘forming’ step is required to make it possible for the memory cell to be used. In the forming step, a positive voltage is applied on the switching layer through its electrodes, creating the filament and changing the resistance of the oxide layer to a Low Resistive State (LRS).

The level remains intact – maintaining the data – until the cell is purposefully reset by applying a negative voltage to break the filament, thus migrating to a High Resistive State (HRS).

Applying positive and negative voltages can cause the cell to switch from one state to the other, encoding binary information by creating either a 1 (LRS) or a 0 (HRS) data bit stored in the memory cell. Once formed, the conductive filament can be broken, then reformed and broken again during successive cycles of erasing and programming the memory cell.

Materials Matter

Thanks to its simple structure, a ReRAM cell is small, fast, easy to stack, and consumes extremely low power. One of the key industry challenges in ReRAM (RRAM) technology development to-date has been in choosing the appropriate resistive material that enables changes to its chemical or physical structure and is then able to restore that structure in a repeatable, low-variability and cost-effective manner. Our ReRAM technology – developed with our R&D partner CEA-Leti – overcomes this challenge.

The material choices we’ve made with Weebit ReRAM are a huge advantage. Weebit ReRAM is based on the most common materials used in fabs today, helping to make it extremely cost-effective and easy to integrate into any CMOS manufacturing flow. In addition, our ReRAM doesn’t require any rare earth materials, and it doesn’t come with any risk of contamination. This sets Weebit ReRAM apart from most other types of emerging memory and contributes positively to our customers’ environmental initiatives.