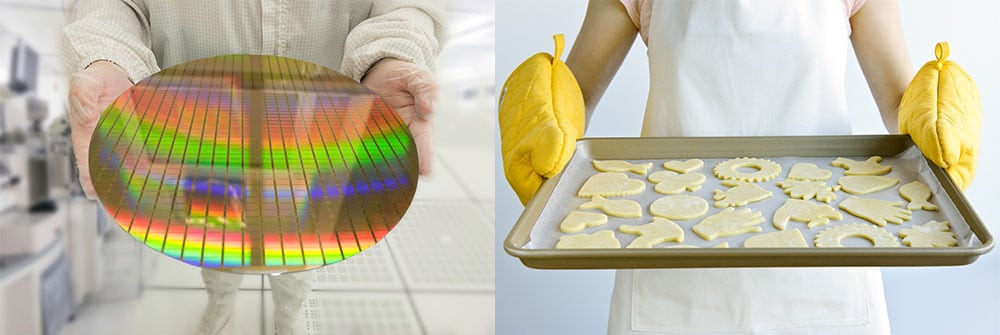

What makes a perfect cookie recipe?

It takes a lot of work to ensure you end up with perfectly formed, equally portioned, evenly baked cookies that look and taste the same every time.

It’s not just the actual ingredients that matter, although those are clearly important (at Weebit we really like chocolate chips), it’s also the specific amounts of each ingredient, the baking time and temperature, and even the particular baking sheet and oven you use. It’s also important that you use a tool like an ice cream scoop to ensure each cookie is the same size. Do you use a cookie press? Roll the dough into balls? Once you have the process down, you’ll need to bake a number of batches under different conditions to make sure they turn out right every time. This is how you create the perfect cookie recipe.

The same is true in semiconductor manufacturing – which is of course quite a bit more complex and sensitive. When a fab gets ready to start manufacturing a new technology, it must work closely with the technology developer to create the perfect recipe – including the materials, process, tools and equipment, and other variables. They must then work together to thoroughly test the technology to ensure high-quality, consistent, and repeatable results.

This process is called Technology Transfer, and in this article, we’ll share with you some of the ingredients that go into making it happen smoothly.

How to Start the Technology Transfer Process?

The technology transfer process begins, as you might expect, with the signing of an agreement between a semiconductor technology provider and a semiconductor fabrication facility (fab).

As soon as we signed our first commercial agreement a few months back with US-based foundry SkyWater Technology, we kicked off the technology transfer process to SkyWater from Weebit and our R&D partner CEA-Leti (at whose facilities we’ve been manufacturing parts to date). The many steps of the process of migrating our ReRAM technology from the development fab to the production fab will continue throughout the coming months.

The initial technology transfer planning stages include a thorough investigation of the toolsets, materials and process flows used by the different companies. While there are often commonalities and crossovers, it is highly unlikely that the equipment and specific processes will match exactly. There will be different equipment, process flows, materials, recipes, quality stacks for specific toolsets, and so on. And even when any of these things are ‘the same’ between different fabs, there might be variations.

In developing our ReRAM technology, we took this into account at the outset. That’s why we not only focused on developing the best technical solution; we developed our ReRAM to be commercially viable. Part of this was choosing the most common materials and equipment used in fabs today. This ensured that when the time came, this part of the technology transfer process would be as straightforward as possible. If we had used rare materials or unique tools, this would have made it much more complex, expensive and risky.

Ensuring Ease of Transfer

While the technology transfer to SkyWater is the first for Weebit, the Weebit and CEA-Leti team members who are managing the transfer have been through this process many times before. That doesn’t mean the process will be fast or easy, but it means the team knows how to prepare for it, and how to execute it.

From the outset of our ReRAM development, the Weebit and Leti R&D teams have ensured that technical data is scientifically gathered, organized, and documented. In addition, Leti has a clear methodology in place based on its deep experience in transferring processes to production fabs. This is one of the many positive aspects of our R&D relationship with Leti. With their methodology as a starting point, the team members then added their own unique input from their past experience and previous technology transfer work, filling out an already robust methodology.

The Complexity of Technology Transfer

The specific process steps used in the development of Weebit’s ReRAM are part of our ‘secret recipe’ so we can’t go into too much detail, but the steps include things like the thickness, density, stress, uniformity, composition, layer stress, surface roughness and layers/process order. At each step, there are quality parameters that the team must adhere to, ensuring that the same parameters are used at both the Leti development fab and SkyWater’s production fab.

The process is so complex and looks at so many variables that even things like tool maintenance are thoroughly documented. For example, every time a certain number of wafers is run through a piece of equipment, it will need to be cleaned, or parts must be replaced. While such schedules are specified by the tool vendor, they can be affected by different processes, amounts of materials, and so on, and must therefore be part of the transfer.

In the technology transfer process, even the smallest variation is important. This can include anything from stress at a certain point in a metal layer to simple things like water evaporation. Everything must be considered and documented.

Once the ReRAM process is transferred, testing begins. Testing is done using a vehicle which basically comprises a mask set with the memory inside—in this case our embedded module. Beyond this, we will move onto the next step – technology qualification (more on this in a future article).

Coordinating across the globe

The team involved in transferring Weebit’s ReRAM to SkyWater is located in multiple locations. The core Weebit team is in Israel, the Leti team is in France, and the SkyWater team is primarily located in Minnesota in the United States. The combined team comprises experts in design and process integration, as well as experts in testing and qualification.

Daily emails, electronic data transfers, weekly Zoom calls and monthly management meetings keep the process moving along. The pandemic has complicated things slightly in terms of in-person coordination, but it hasn’t impeded progress, and we are progressing as planned.

Perfecting the recipe

While we proceed with the technology transfer to SkyWater, we are also focused on perfecting the recipe for memory cells with even better performance. We are pleased to be continuing our work with the experts at Leti and are delighted with the new relationships we’re building with our partners at SkyWater.

We will continue to provide updates as we progress further down the path.

In the meantime, if you’re looking for that ‘perfect’ chocolate chip cookie recipe, you can find the best cookies ranked on various key criteria by a group of cookie lovers here. Enjoy!