The Weebit ReRAM Advantage

Today we are seeing an explosion of innovation in electronic devices – with ever-more immersive and intelligent technologies fast becoming integral parts of our lives.

The industry needs a new type of NVM to support this new era of devices and applications.

NVM must be extremely low power to support IoT and battery-operated devices. It must have excellent endurance and retention – even at high temperatures and in harsh conditions – to support long-lifecycle automotive and industrial applications.

And it must be scalable to advanced process nodes to support emerging applications such as AI and advanced IoT.

Our highly scalable ReRAM (also called RRAM) is an ideal successor to today’s NVM solutions. Weebit ReRAM beats flash on key metrics including cost, power consumption, endurance, access time, and more. It also wins on these metrics when compared to other forms of emerging NVM.

High Endurance

Endurance – the number of times a memory can be reliably written in its lifetime – varies significantly between different memory types. Weebit ReRAM typically has 10x-100x better endurance than flash, handling between 100,000 and a million write cycles versus the typical 10,000 program/erase cycles that flash can manage. This means Weebit ReRAM can support applications that require more frequent memory updates such as automotive and security – where frequent updates are typical as well as data logging.

Excellent Data Retention even at High Temperatures

A memory’s data retention time refers to how long stored data will be saved on the device at the specified temperature. The retention of most NVM devices is measured at ~10 years @ 85°C or 105°C, but they normally can’t achieve such retention at higher temperatures. Weebit ReRAM can maintain its reliability at high temperatures, retaining data for up to ten years at 150°C or even 20 years at 125°C. This makes our ReRAM a great fit for automotive, power, and industrial applications.

Low Power Consumption

While the factors impacting NVM power consumption can vary widely based on application, Weebit ReRAM is shown to consume significantly less Read, Write and Standby power than embedded flash, contributing to longer battery life for many devices. The low voltage levels used for these memory transactions, coupled with its fast memory access time, greatly reduce the overall power consumed by Weebit ReRAM.

Fast Access Time

Weebit ReRAM has direct read and write functions and is bit addressable, leading to fast cell Read/Write and enhanced system performance. Flash needs to access entire blocks of data every time it erases data, leading to slower write access time. Weebit ReRAM has typically 100x faster write access time than flash, and it’s also faster than other NVMs.

Tolerance to Environmental Conditions

Radiation tolerance is an important consideration in numerous medical, industrial and aerospace applications. Flash has limited radiation tolerance, so it requires redundancy or shielding when used in these applications, leading to added cost. Weebit ReRAM cells can withstand up to 350x more radiation than flash.

Immunity to electromagnetic fields is another important consideration for many similar applications. MRAM has, by definition (being magnetic memory), limited tolerance to electromagnetic fields. ReRAM cells, unlike other emerging memory technologies, are immune to electromagnetic fields. Weebit ReRAM is also thermally stable and operates consistently at a broad range of temperatures.

BEOL Technology

An important benefit of ReRAM is that it is a Back-End-Of-Line (BEOL) manufacturing technology that is easy to integrate with any Front-End-Of-Line (FEOL) technology. Flash is integrated in FEOL alongside many key analog components – often forcing compromises that lead to lower performance, larger size, and higher cost. Since ReRAM (RRAM) is integrated in BEOL, there is no need for compromise.

The fact that ReRAM is BEOL also means that it only needs to be adapted to a geometry in a fab once for all the variants of that geometry (low power, high voltage, etc.), unlike flash and other FEOL technologies which need to be adapted separately to each variant.

Lower Cost and Complexity

Weebit ReRAM is based on the most common materials used in fabs today, it uses standard tools and process flows, and it doesn’t require special equipment or additional floor space. All of this makes it easy to integrate our ReRAM into any CMOS manufacturing flow.

Compared to other emerging NVMs, ReRAM is a much simpler and cost-effective stack to produce. The Weebit stack comprises two layers between electrodes. MRAM comprises more than 10 layers, and these layers can be so thin that they are often difficult to accurately deposit and monitor. Weebit ReRAM requires only two additional masks, compared to more than 10 added masks for Flash. As a result, Weebit ReRAM only adds ~5% to the wafer cost, whereas flash and MRAM both add ~20-30%, and even 40% in some process nodes.

Our ReRAM is also inherently lower power than flash, and it consumes fewer resources to manufacture. As a result, it has a smaller GHG (greenhouse gas) emission footprint. In addition, ReRAM doesn’t require any rare earth materials, and the materials it does use don’t have a high risk of contamination.

Designed for Security

Weebit ReRAM demonstrates significant security-related advantages, enabling it to better protect its content from hacking attacks, and making it more difficult to reverse engineer.

Unlike floating gate devices such as flash, ReRAM does not use any charges or other particles, so it is more difficult to sense or change its internal state using electron beams. ReRAM is also immune to electromagnetic fields, enabling it to easily withstand magnetic attacks. In addition, because the ReRAM bit cell is deeply embedded between two metal layers integrated at the back-end-of-line (BEOL), it is more immune to optical (laser) attacks. Lastly, careful design of Weebit ReRAM cells and associated control logic allow it to perfectly balance its power profile when reading its content, making it more immune to power analysis hacking.

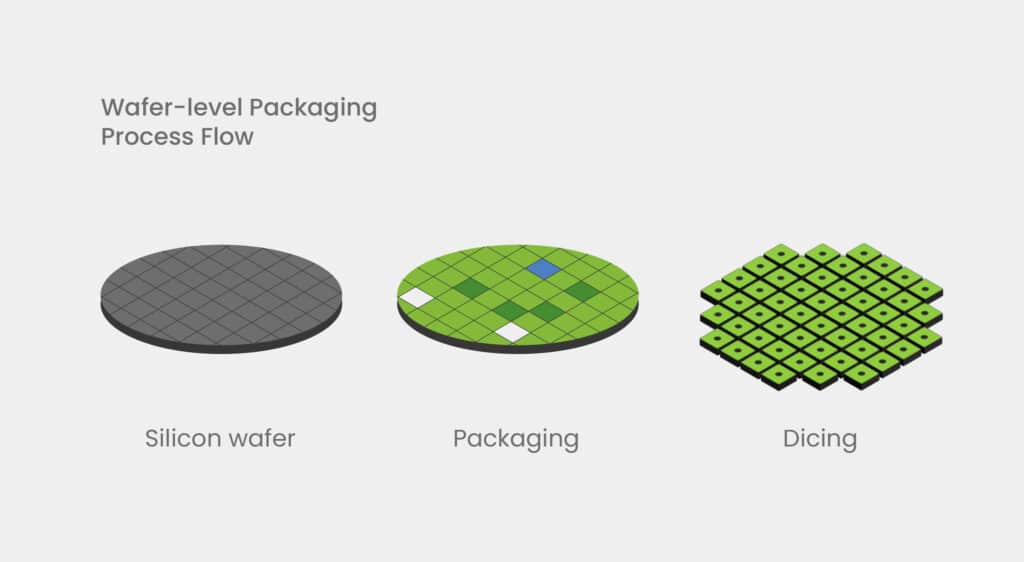

Enabling Wafer Level Packaging (WLP)